Corrugated panels are metal building component panels made in a repeating wave pattern and well-known for their design. They are exceptionally durable, stable, and widely used for more than 100 years. Metal corrugated roofing panels were the first to be produced in massive amounts in North America.

Many Toloka Corporation clients know how stressful it can be to decide what type of material to use for a roofing or siding project. That is why we are here to help you narrow down the selection, depending on the kind of project and material you want.

Types of Corrugated Metal Panels

Briefly, corrugated metal panels are manufactured using rippled metal sheets, a rigid, still lightweight material with water resistance. Panels are used for roofing, flooring, and siding, commonly for houses, storages, mass-producing facilities, and farms. Toloka Corporation is specialized in providing top-quality materials and installment works, including metal panels. The difference between different corrugated metal panels depends on their gauge and board size. Additionally, there is a wide range of colors, including smooth and stucco patterns.

1-¼” Corrugated panels

This type of panel is usually made with galvanized coating and lighter gauges:26-28-29 gauge. It is commonly used in decorative and industrial projects because of its thin profile. The standard size is 26” wide and three different lengths of 8’, 10’, and 12’ long. Our clients can choose from any panel profile to be used, using aluminum and stainless steel coatings.

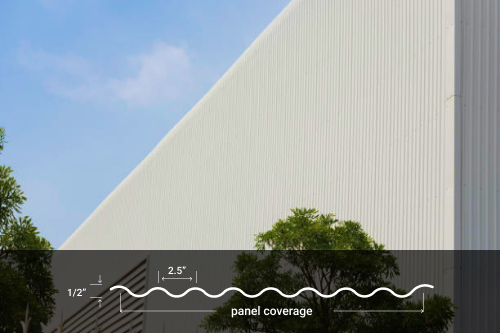

2-½” x ½” Corrugated panels

This type of metal panel can be found practically everywhere, as they became an unspoken standard for many years. It is usually used for farm and barn projects, implying their simple and standard modern look. Guessing what 2-½” stands for? It is a distance from the peak of one ‘bump to the peak of the next, with a specified height of ½”. Usually, it comes in a G-90 adhesive coating finish, but we would be glad to provide you with any type of coating material you require. This list may be expanded more than fiberglass, aluminum, steel finishes.

2,67”x 7/8”Corrugated panels

This profile is made with a deeper groove for corrugated style to look more distinguished. It has a larger span, with a thicker gauge and the panel overall. It is commonly used for roofing projects because its deep groove runs more water than any corrugated metal panel, and has a unique S-style, widely recognized. Typically, this type of material is made using standard lengths of 8’, 10’, and 12’ long and 18,20,22, or 24 gauge thick. Usually, it comes in stainless steel or aluminum mill coating with smooth and stucco-like patterns. It can also be painted in any color you want.

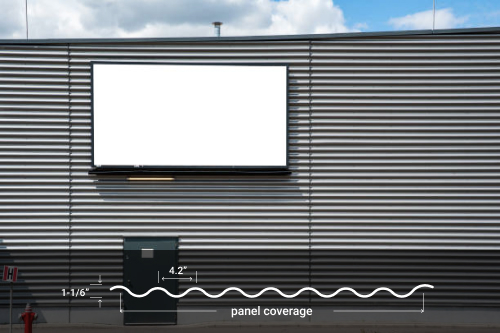

4.2” Corrugated panels

Originally this type of panels was made in a concrete version, but with the development of metal roofing, they were replaced. It has a similar look to the earlier mentioned 2-½” panel but has a more prominent and striking appearance. Usually, it is used practically everywhere: roofing, siding, or decorative elements. When it comes to sizes, 4.2” shows the distance between one peak and the next one, with a standard height of 1-1/16”. It comes in an aluminum smooth or stucco finish, with a possibility of adding stainless steel coating, and any color on a palette can be added to it. We can indeed say that this one is the most “‘wavy” style available on the market.

Advantages and disadvantages of corrugated metal panels

When choosing metal panels, there are still some choices: what type of profile to choose, what color it should be, how to compose other siding or roofing materials. At first, we can assure you that corrugated metal panels are the most popular choice among our clients because of their longevity, durability, easy installation, and other advantages of metal.

The Pros Of Corrugated Metal Panels

Always available

Corrugated metal panels are available for the market for more than a century, which shows us that they came a long way, modernizing and developing their quality. Nowadays, metal siding and roofing can be found everywhere and even installed by yourself, but we strongly suggest inviting an experienced and qualified contractor. Toloka Corporation will save you time and provide you with the corrugated metal panel installation warranty.

Weather withstanding and durable

For many years vinyl and wood sidings were used as standard products for any type of siding project. According to our experience, these materials are often damaged or even torn off during wind storms and replaced after natural disasters. Because of that, Toloka Corp strongly advises its customers to invest their hard-earned money in corrugated metal panels. Since metal panels are made of metal alloys and covered with paint, it does not attract any type of pests or ants. Also, you shouldn’t worry about your health, all of our materials are friendly to people and the environment. Because it is not absorbent, there is no possibility of being damaged by rain, wind, or mold.

Commercially successful

When it comes to purchasing corrugated metal panels, Toloka Corporation makes sure that our clients receive qualified and fast installation. Since installation usually takes not a lot of time, its budget costs are low. Moreover, metal panel roofing and siding don’t require any special clips or extra accessories. They are easily installed using only galvanized fasteners, which will not rust, exposed to sun, wind, and rain. Properly installed, metal panels don’t require a lot of maintenance or replacement in the future, unlike cedar siding, for example, so our clients don’t have to worry about spending more money on their siding.

Disadvantages of corrugated metal paneling

Frequent checking

The main reason why you should take a look at your metal panel siding and roofing, especially after any severe weather, are exposed fasteners. Homeowners should check on their metal panels every time they think screws may be damaged. At Toloka Corporation we believe, that thorough inspection might save our clients from significant problems in the future.

Metal panels with exposed fasteners

This type of siding requires hundreds of screws to keep the roof in place. With inappropriate installation, they will become loose, so your roofing can be exposed to leaks. They also should be replaced or tightened every time you provide maintenance to avoid leakage.

Not suitable for flat roofs

It is firmly not recommended to install corrugated metal roofing on a flat roof because lack of steep pitch for rainwater to runoff. It may cause a significant problem with the exposed fasteners, as they become more vulnerable to leaking, which potentially will result in high-budget roof renovating.

How to choose a suitable corrugated roofing

Different types of metal roofing and siding appear the same, and there is a variety of metal panels to pick up from. At Toloka Corporation we know, that as a general rule, the better quality metal you purchase comes, the more costly materials and installation.

Even if you decide on something middle-class, with a classic gauge: not big but not too weightless, we will have something for you. Luckily, with corrugated metal roofing, you’ll still get a durable and long-lasting roof material. However, we encourage you to go with a more prosperous option.

Corrugated metal roofing and siding panels are commonly manufactured from coated steel to make low weight and withstanding material. Several materials can be made using zinc or aluminum coating, resulting in more expenses but will save the house’s exterior for a longer time.

There comes the tricky part – color choosing. Corrugated metal can be made in various colors and patterns depending on which type of metal you choose. Most of our clients prefer the classic and minimalistic appearance of the metal itself, while you can choose a more contemporary look with atypical colors of your siding. For example, deep red siding can be combined with light brown or black roofing.

How to keep up your corrugated panel siding and roofing

We’ll assume that you already have selected the particular metal, seam type, gauge, and color for your roofing or siding material and that it was installed on your house correctly.

Properly storage and install

You should be aware of some issues: corrugated metal panels may have problems if they aren’t installed right. Toloka Corporation makes sure qualified professionals provide the installation, the material is appropriately stored, and the ordered amounts are correct.

Clean your metal siding frequently

Metal siding and roofing of any material need maintenance for the surface, at least to make sure it looks great. You can wash it with a low-pressure garden hose to keep it free of dirt, debris, and muck. If you decide to don’t clean your siding and roof, it can develop mold and moss, resulting in corrosion and surface damage. But don’t get too upset; almost all metal panel surfaces are smooth, making them easy to clean.

Keep the gutters clean and empty

We should remind you about the importance of keeping your gutters clean. We already mentioned that this material isn’t vulnerable to rain or snow, but when it is accessible to contact standing water, there could be some bad consequences. If gutters are blocked, your metal siding can be exposed to prolonged contact with water, which can cause visible damage, shortening the lifetime of your metal panels.

Check your corrugated metal panels for cracks

One of the most common mistakes is that metal panels’ surface damage isn’t significant because it doesn’t affect steel. Well, there is a piece of truth in it, but any covering crack can cause a great deal of structural damage in the future. If there is a particular factor that causes dents in your metal siding, for example, tree branches, it will cause harm to your exterior.

Look after your siding

We strongly advise our clients to inspect their corrugated metal panels after severe weather conditions, such as hailing winds and heavy rains. Look out for any surface damages, such as cracks, corrosion, and deep scratches. Moreover, let us know if you notice any leaks, wet spots under your roof or siding, and loose screws. Our maintenance crew is specially trained to help you out with upkeep if needed. It is strongly recommended that your corrugated metal panels should be inspected by professionals at least once in two years.

To sum everything up

We can only congratulate you if you decided to apply corrugated metal panels to your house! It is a perfect option for those who appreciate durable, lifetime lasting, and low maintenance materials. At Toloka Corporation we think, that excellent materials are equal to a great life. But, we strongly advise you to stick to our maintenance tips to make sure your roof lasts as long as possible.