A Long-Life Roofing Decision

A lot of building owners consider metal roofing to be the best choice. However, just typing “metal roofing companies near me” in Google search means the precious time has to be wasted on picking up the proper manufacturer. TOLOKA General Contractor&Builder want our customers to spend days enjoying their life instead of surfing the web. Our company is working with the best metal roofing contractors in Calgary, Red Deer, Vancouver, etc. We believe there’s a solution for every single client. And depending on the wishes, budget, and designs, our team would help you construct the best roofing in the western states of Canada.

More About Pros and Cons of Metal Roofing

Your life is full of choices. And even choosing the right roofing is a complicated one. To resolve this issue, we need to tell you more about the pros and cons of metal roofing.

So, on the one hand, we have:

More than 60 years of roofing life sounds better than renovating it every ten years.

Metal roofing is when you need to rely entirely on the choice of product and a proper installation. This roofing type is resistant to strong winds, corrosion, snow, hail, mold, etc.

No high-priced maintenance, just periodical inspection is required. It means looking for leaves or branches that could get stuck on the roof twice a year and after storms. The dirt or stains usually are washed by rain. If not, there are easy cleaning methods.

Metal roofs include up to 95% recycled content depending on the material. In addition, every metal detail is 100% recyclable, though there is another building-related waste.

No need to fear the flames, lightning strikes, or wildfires. Metal roofing has high fire resistance.

With simple calculations, we can state that paying more for a metal roof once in 60 years is more economical than renovating any other type of roofing once in 10-15 years.

As metal roofing reflects solar radiant heat instead of absorbing it, your cooling costs would significantly decrease.

And on the other hand, there are:

Almost half of the price for metal roofing is installation labor. So working with better metal materials, you can get a large sum of money.

When deciding on particular types of metal, you won’t be able to step onto the roofing without causing damage. Large hail or big branches may also create visible marks.

Extra decking has to be included in the overall cost of the roof if you don’t want to hear loud noises during heavy rain or thunderstorm.

If metal roofing appears to be of poor quality, it may rust. It influences the whole look of the house.

As you see, more pros, fewer cons. And TOLOKA General Contractor&Builder would be happy to meet your needs, improve any destructive features of metal roofing and create a perfect picture of your home.

Choosing The Right Material

Metal roofing can be used for various buildings: commercial, residential, architectural, or industrial projects. And as the word “metal” has an expansive meaning, it’s time to determine the most common types of metal roofing on the market. This would help you to understand which material fits your design the best.

Aluminum Metal Roofing

The lightweight of this material can make you think it’s not durable. But that’s not true. This is the case when strength is achieved through easy maintenance, color variation, and long-life durability. Moreover, gable flashing for metal roofs is easily realized with aluminum-made panels.

If you live in an area of a humid climate, aluminum metal is just for you. It’s resistant to corrosion. Besides, having heavier thickness aluminum panels installed, you’ll increase protection against dents.

Another thing is that aluminum has fewer colors. It may seem a disadvantage for some customers; for others – time to get back to basics.

The cost of aluminum metal roofing depends on the panels’ thickness. Comparing to other roofing materials, this one is quite expensive.

Zinc Metal Roofing

One more option that is made to stand the test of time is zinc. Its popularity among building companies is constantly increasing. Many clients pick zinc metal roofing among other metal roof choices.

Approximate longevity from 60 to 100 years is one of the numerous zinc pros. Of course, this comes together with a reasonably high price. But this is what real eco-lovers pay for—no toxic run-off or ground pollution near your roofing. Coated or uncoated zinc also can reduce the amount of energy absorbed into a building.

Zinc metal roofing seems to be magical with the self-healing feature it has. A specific outer protective layer corrects itself over time from any marks of corrosion, scratching, or panel markings. However, if improperly coated on the underside of the panel, water can cause damage to the metal. Therefore, the need for good ventilation is essential to keep zinc roofing well-maintained. Oil canning is also recommended in some cases.

Buildings with zinc roofing are full of grace as this metal is soft and can realize the most sophisticated projects.

Copper Metal Roofing

No extra coating is required for copper metal roofing. It’s strong and durable, famous, and loved in many Canadian cities. Why? Because it’s ideal for areas with regular heavy snowfall. Fire and mildew resistance completes the list of copper advantages. But if you choose this material, be ready to pay more for its quality. And when we say more, we mean that copper roofing is the most expensive roofing material.

The look of roofs made of copper is terrific. However, in years, this metal is aging and developing a blue-green covering called a patina. Some people don’t like this as the patina can turn into rich green or dark bronze.

Copper metal roofing can last more than 100 years in some instances. This is why you can observe it on many historic buildings.

Copper roofing has a unique possibility to be soldered. This process creates a weather-tight roof with a roof, wall flashings, and gutter joints connected.

Stainless Steel Roofing

When we talk about metal roofing, we probably picture steel roofing. However, as simple steel panels can easily rust, most manufacturers cover zinc or zinc-aluminum with an anti-corrosive coating. That’s why we usually call it stainless steel.

This material is relatively low-priced but with high strength. Stainless steel roofing would give you up to 60 years of a nice look. It has been produced for a wide temperature range to reflect heat away from the building and stay uncracked during cold weather.

Different finishes are available for this metal roof painting so that your roof will suit other construction elements. One precaution should be taken during stainless steel roofing installation: a good draining system. This will exclude the possibility of standing water remaining.

Galvalume-Coated Steel

This roofing system was introduced in the 1970s by Bethlehem Steel. Galvalume roofing represents a combination of three materials: steel, aluminum, and zinc. The unique hot-dipping process creates a product that has the best characteristics from its ingredients.

Galvalume coated steel roofing is NOT recommended for buildings where animals are regularly held or in coastal environments.

The toughness of zinc is strengthened by aluminum rust resistance. So, galvalume-coated steel lasts up to 60 years without extreme signs of corrosion.

During any metal roofing installation, there are formed cut or exposed edges. The self-healing feature of galvalume roofing helps to control the red rusting on them.

Oil canning is required and can cause an aesthetic concern. Though with an experienced contractor, you can minimize this impact.

Do you hesitate what to choose?

Our consultant will answer all your questions, just send your contacts and we will call you within 20 minutes. Or send your questions to our e-mail.

GET A FREE CONSULTATION

Galvanized Steel

A similar hot-dipping process is implemented for galvanized steel. This is the way how a protective zinc coating is applied to steel or iron. Galvalume-coated steel somehow replaced galvanized steel. However, when an aged metallic look is desired, it’s better to use galvanized steel.

The price of this roofing material is quite mid-level. However, it’s better to build such roofs in drier climates as moisture can quickly corrode galvanized metal. And lacking self-healing, galvanized steel will continue to red rust.

Lead Roofing Material

Lead is one of the oldest roofing types chosen for durability. It’s mouldable and suits different types of building designs. Lead roofing cannot catch fire but can melt under extreme heat; it’s resistant to corrosion, radiation, and sound but has a high price.

However, lead is known as toxic material. That’s why such roofing is used mainly for industrial or commercial buildings.

Panel Styles of Metal Roofing

- Standing seam

Metal panels are interlocked together, forming a vertical seam. Clips and fasteners are hidden, making standing seam roofing the better option.

- Exposed fastener

The fasteners’ heads are installed on the top and are visible. The fasteners go directly through the metal and into the roof deck. It’s a more economical choice.

- Stamped profiles

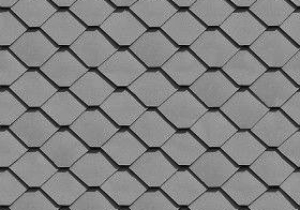

If you consider setting a metal roof over shingles, we have a better variant: metal stamped profiles. Pick up one of three points – shakes, shingles, or tiles. The durability and cost of the actual metal are still present.

Metal Panel Seam Types

- Snap-lock

Specially roll-formed metal panels are designed to avoid damages during installation. No hand or mechanical seaming is needed.

- Mechanical seam

The same roll-formed metal panels are put together with a hand or mechanical seamer. Again, single or double locks are possible.

- Tee panel

A cap is used to connect two panels, so they resemble the letter “T.” mechanical seamer is used to lock the panels.

- Exposed fastener lap seam

The overlapping ends of the lap panels are fixed down to the deck from the top of the panel.

Metal Panels Striations

For lovers of raised-rib metal roofs, there exist so-called patterns of panels:

- Flat

- Ribbed: V-ribs; Bead; Pencil

- Striated

- Corrugated

- Clip relief

For detailed information about metal roofing, warranties and prices, contact TOLOKA General Contractor&Builder.

GET IN TOUCH

Contact Us